Cleaning large filling machines is a crucial task in maintaining hygiene, ensuring product quality, and prolonging the lifespan of the equipment.

In industries such as food and beverage, pharmaceuticals, and cosmetics, proper cleaning protocols are essential to prevent contamination and comply with health regulations. Here’s a comprehensive guide on how to effectively clean large filling machines.

Preparation for Cleaning

Before starting the cleaning process, it is essential to prepare adequately. This includes:

Shutting Down the Machine: Ensure that the filling machine is turned off and disconnected from the power source to prevent accidents.

Gathering Cleaning Supplies: Collect all necessary cleaning supplies, including detergents, sanitizers, brushes, cloths, and protective gear such as gloves and goggles.

Reviewing Manufacturer Guidelines: Consult the manufacturer’s manual for specific cleaning instructions and recommendations for cleaning agents that are safe for the machine.

Disassembling the Machine

To clean the filling machine thoroughly, it may be necessary to disassemble certain parts. Follow these steps:

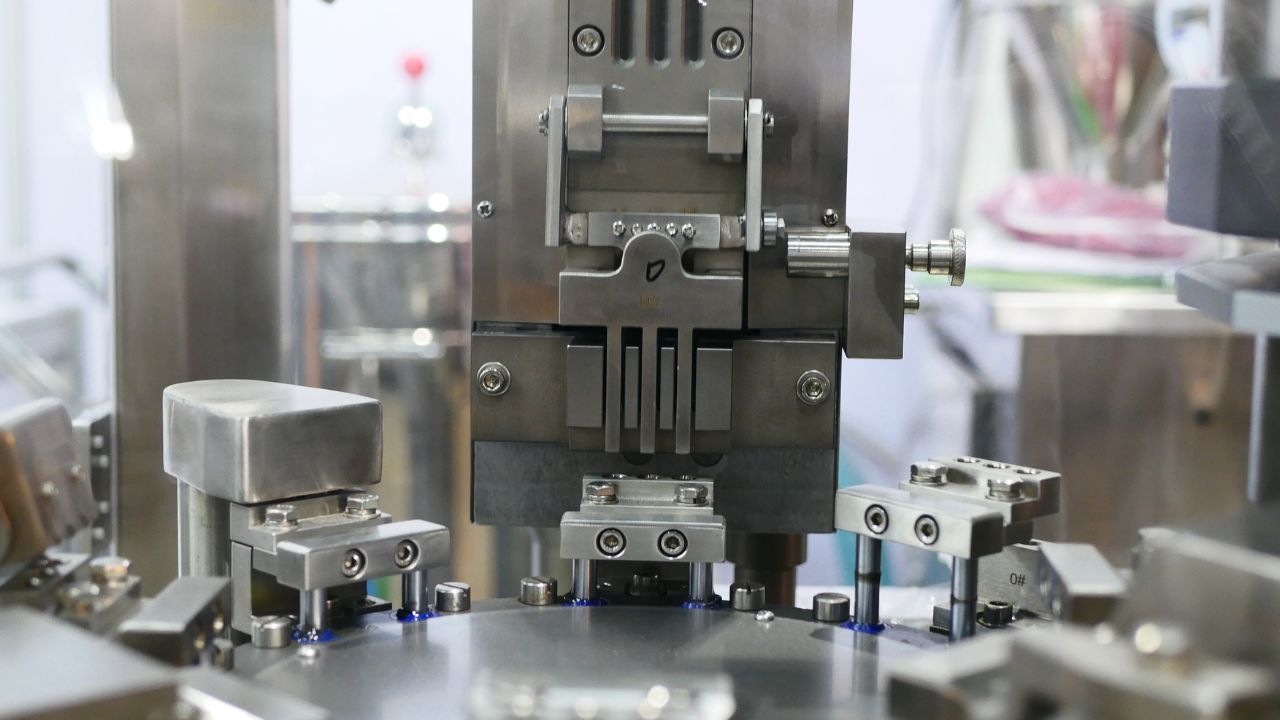

Remove Product Contact Parts: Detach all components that come into direct contact with the product, such as nozzles, filling heads, and hoppers. This allows for a more thorough cleaning.

Label Parts: As you disassemble the machine, label each part to ensure easy reassembly later. This is especially important for complex machines with many components.

Cleaning the Components

Once the machine is disassembled, it’s time to clean the individual components. Here’s how to do it:

Soak in Cleaning Solution: Place removable parts in a basin filled with warm water and an appropriate cleaning solution. Allow them to soak for a specified time to loosen any residue.

Scrub Thoroughly: Use brushes or cloths to scrub each part, paying special attention to hard-to-reach areas. Ensure that all residues, including product buildup and contaminants, are removed.

Rinse with Clean Water: After scrubbing, rinse each component thoroughly with clean water to remove any cleaning solution. This step is crucial to prevent any chemical residues from contaminating future products.

Cleaning the Machine Interior

After cleaning the removable parts, focus on the machine’s interior:

Wipe Down Surfaces: Use a damp cloth with a suitable cleaning solution to wipe down all accessible surfaces of the machine. This includes the frame, control panels, and any areas where product residue may accumulate.

Use Compressed Air: For hard-to-reach areas, consider using compressed air to blow out any remaining debris or cleaning solution. This is particularly useful for electronic components and sensors.

Sanitizing the Equipment

Sanitization is a critical step in the cleaning process, especially in industries where hygiene is paramount:

Apply Sanitizer: After cleaning, apply a food-safe sanitizer to all surfaces and components that come into contact with the product. Follow the manufacturer’s instructions for dilution and contact time.

Allow to Air Dry: Let the sanitized components air dry completely before reassembling the machine. This ensures that no moisture remains, which could lead to microbial growth.

Reassembly and Final Checks

Once all components are clean and dry, it’s time to reassemble the machine:

Reattach Components: Carefully reattach all parts, ensuring that they are secured properly. Refer to the labels you made during disassembly to avoid confusion.

Conduct a Final Inspection: Before powering the machine back on, conduct a thorough inspection to ensure that everything is in place and that there are no leftover cleaning materials.

Conclusion

Cleaning large filling machines is a vital process that requires attention to detail and adherence to safety protocols. By following these steps, manufacturers can ensure that their equipment remains hygienic, efficient, and compliant with industry standards. Regular cleaning not only helps maintain product quality but also extends the lifespan of the machinery. If you need to choose the right filling machine, you can click confilling.com.