In the world of industrial production, mold manufacture is a pillar that is essential to turning imaginative designs into practical, mass-produced reality. Fundamentally, mold manufacturing entails the painstaking creation of molds, frequently made of durable materials like metal, that serve as the molds into which substances like plastic, metal, or rubber are injected or formed.

These molds, which are sophisticated in design and exact in execution, are the unsung heroes behind the reliable duplication of numerous items that are present in every aspect of our everyday lives. click here for further information on the subject. Mold manufacturing is the unseen engine that propels the efficiency and accuracy of contemporary manufacturing processes, from the delicate components of car engines to the plastic cases of electronic devices.

Why is Mold Manufacturing Important to Different Industries, and What Is It?

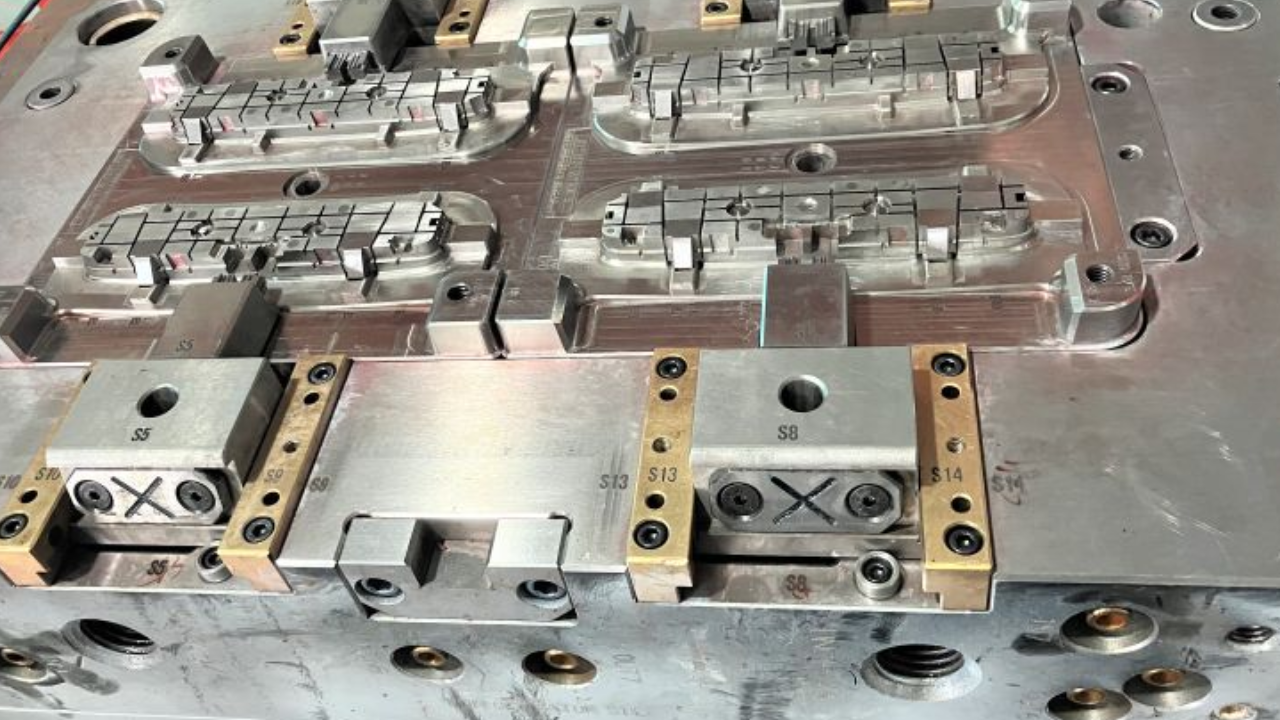

Mold manufacturing is a specialized process that entails the development of molds, often made of sturdy materials like metal, to copy identical things on a large scale using different manufacturing techniques like injection molding, die casting, and compression molding. Due to its crucial role in establishing mass production and guaranteeing product uniformity, mold manufacturing is significant across many industries.

Molds enable producers to produce vast quantities of goods with accuracy, efficiency, and consistency in terms of both design and quality. This procedure is essential in the manufacture of a diverse range of commodities, from simple consumer goods to complex industrial components. Complex designs may be produced efficiently and affordably utilizing mold manufacturing, which is not always possible with conventional production techniques.

Common Kinds of Mold Production

Different mold types, each created for particular uses and production methods, are used in the manufacture of molds. Here are a few typical types utilized in the creation of molds:

Injection Molds:

For the large production of plastic components, injection molds are commonly employed. Melting plastic is injected into a mold cavity where it is allowed to cool and solidify. Once it has set, the mold opens, releasing the formed portion. Frequently used in the manufacture of consumer goods, automobile parts, and electronic components.

Die Casting Molds:

In the die-casting procedure, molten metal is pushed into the mold chamber at high pressure using die-casting molds. This causes the metal to solidify quickly, generating intricate and highly accurate metal components. Utilized frequently in the automotive sector to make engine parts, chassis parts, and other metal components.

Compression Molds:

To shape a material into a given shape, compression molds use both heat and pressure. The material is compressed and shaped under pressure after it is heated and placed inside the mold cavity. It is typical in the manufacturing of thermosetting polymers, rubber parts, and composite materials.

Blowing Molds:

To create hollow things like bottles and containers, blow molds are employed. A molten plastic tube is extruded, put in the mold, and then inflated with air pressure to take the shape of the mold. often employed in the production of bottles and containers by the packaging industry.

Rotational Molds

In rotational molding, a mold is heated and rotated around two perpendicular axes. As the substance melts and solidifies, coating the interior of the mold and forming a hollow part, it is frequently plastic in powder form. It is used for huge, hollow objects like playground equipment, containers, and tanks.

Molds for Thermoforming:

In the thermoforming procedure, a plastic sheet is heated and shaped over a mold to produce a three-dimensional shape. The method uses thermoforming molds. After that, the created portion is cut to the required size. It is frequently employed in the manufacture of disposable containers, trays, and packaging.

Extrusion Dies

When a material is pressed through a die to produce a continuous profile or shape, extrusion dies are employed. Plastic profiles and pipes are frequently produced using this procedure. often used to make pipes, window profiles, and other extruded plastic items in the construction sector.

Plastic Molds:

Molding rubber materials requires the use of rubber molds. Compression molding, injection molding, or transfer molding may be used during the molding process, depending on the properties of the rubber and the intended product. Frequently used in the manufacture of rubber gaskets, seals, and automobile parts.

Conclusion

A key component of the industrial sector, the manufacture of molds enables the mass production of a wide range of goods. This industry is always evolving, becoming more productive, efficient, and capable of creating ever-more intricate designs thanks to technological advancements. Mold production will probably continue to be on the cutting edge of assuring product quality and consistency as manufacturing processes advance in a constantly shifting industrial environment.